Sona Flex

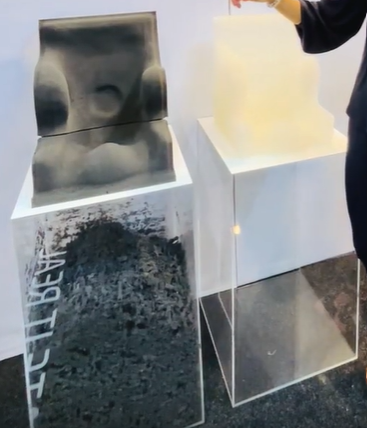

Programmable FoamⓇ is an innovative technology that enables the customization of foam densities to meet specific patient needs. By allowing adjustments in firmness and flexibility, it provides an optimal balance between support and comfort. This versatility makes Programmable FoamⓇ ideal for orthopedic devices, custom seating, and mattresses. It enhances patient care by ensuring that each product is tailored to individual preferences, improving overall satisfaction and therapeutic outcomes.

SonaTECH TPU

The automatic spool change system ensures non-stop printing, while the ability to pause printing provides users with greater control and flexibility during the printing process.

TPU Elastic, Flexible, Washable & Fire Retardant

1500 x 1060 x 1450 mm - 150 kg

Sustainable production

3D printing with the Sona Printers Range represents a groundbreaking production method that significantly reduces waste compared to traditional seat carving. This innovative approach minimizes dust by 90% compared to traditional methods. By embracing these new production methods, you commit to providing efficient and sustainable solutions for patients worldwide.

Don’t miss the latest updates and news for each of our solutions. You can unsubscribe at any time.

* Please fill out the required fields