Endless design possibilities with Cube software

In the field of orthopedics, precision, customization and efficiency are crucial for creating medical devices that meet the unique needs of each patient. However, the process of designing these orthopedic solutions can often be complex and time-consuming, requiring specialized tools to streamline the task. Cube changes the game. This orthopedic CAD/CAM software, specifically developed for orthopedic professionals, revolutionizes the way custom devices are created, offering an intuitive and versatile platform to transform patient scans into tailor-made solutions. Cube is more than just a design tool; it provides a practical answer to the daily challenges faced by orthotists and prosthetists, equipping them with innovative features that optimize design while meeting clinical requirements.

Cube : the go-to software for orthopedic professionals

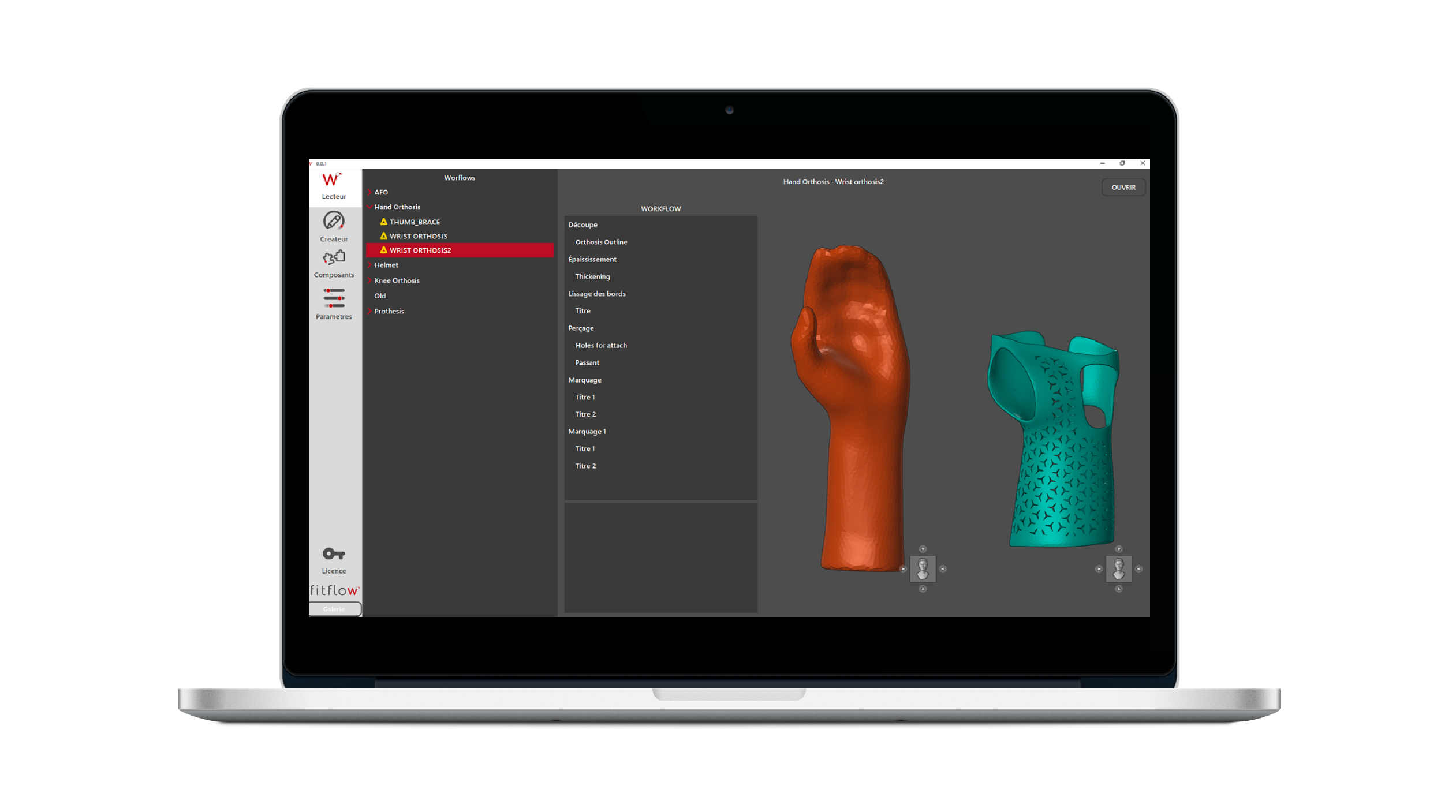

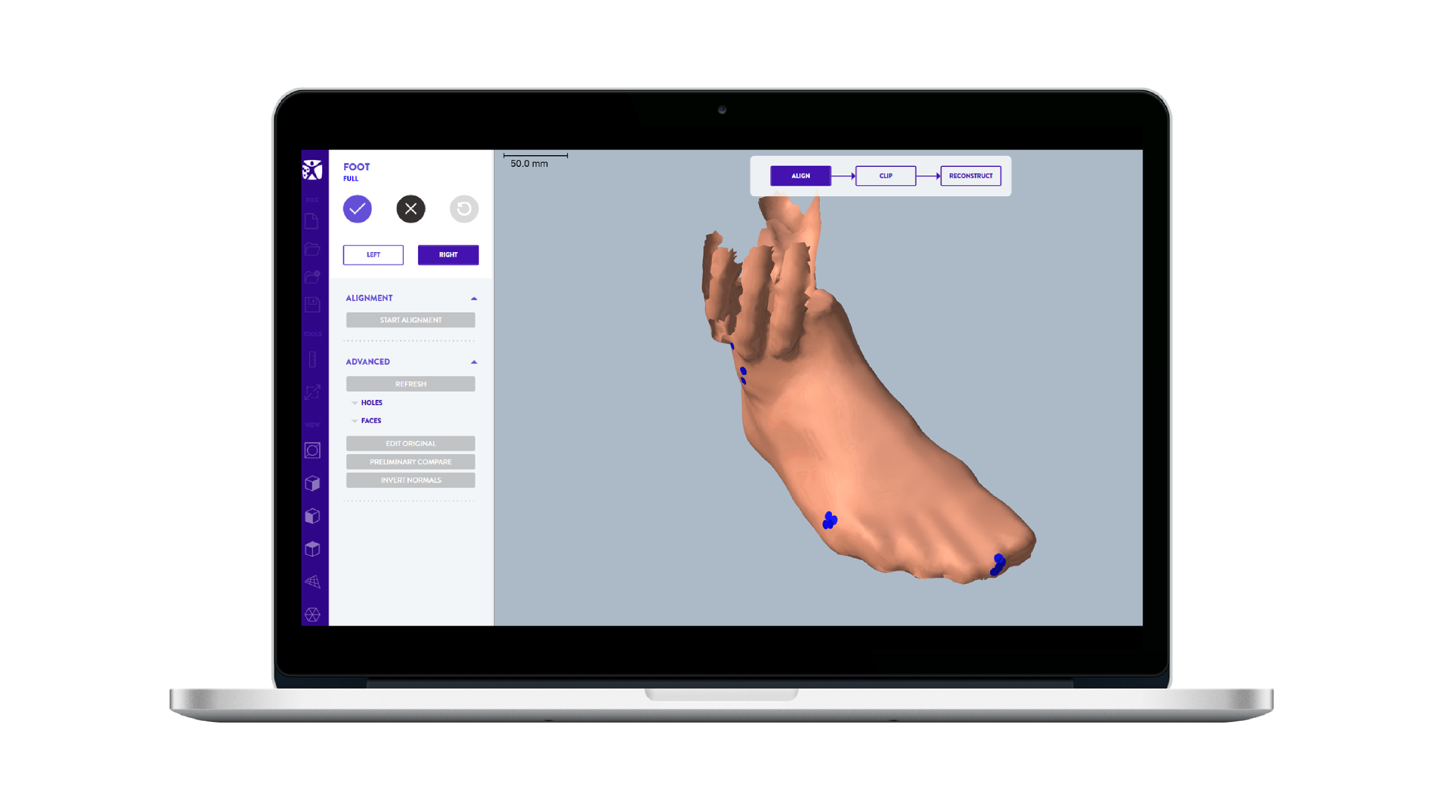

Cube represents a significant shift in how orthopedic devices are designed, offering orthopedic professionals a versatile and powerful tool to create custom solutions with accuracy and ease. Designed specifically for the needs of the orthopedic field, Cube enables the quick transformation of patient scans into functional, patient-specific designs. The software integrates seamlessly with scanning devices and CAD systems, allowing professionals to create devices that are both practical and tailored to each patient’s unique anatomy.

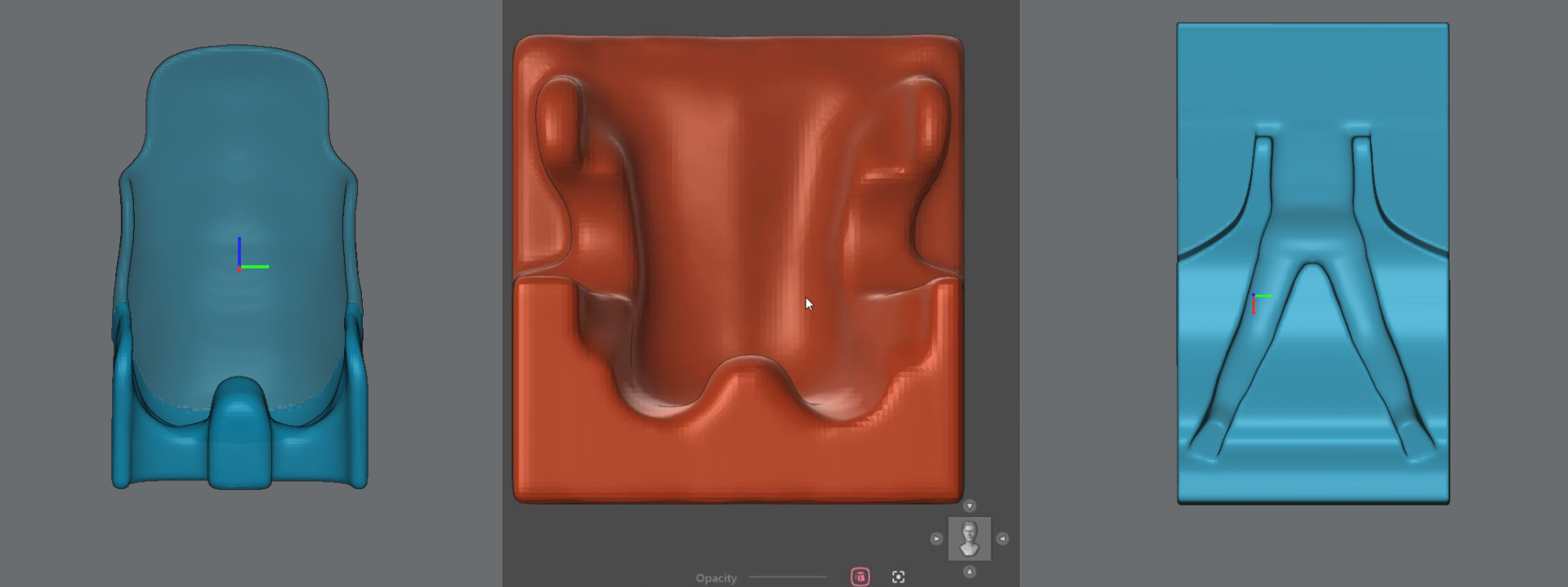

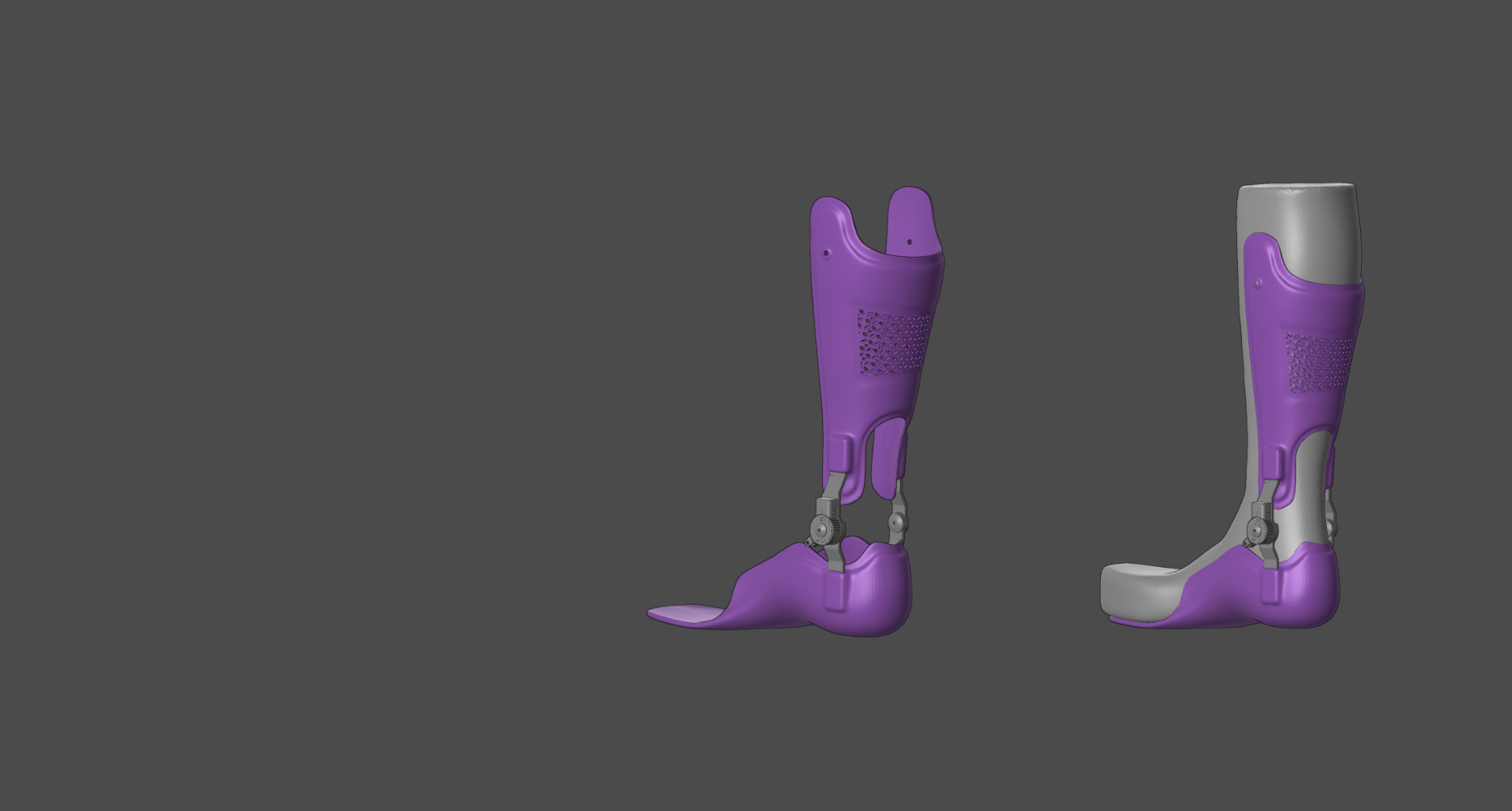

One of the standout features of Cube is its support for both positive and negative forms. This dual capability expands the possibilities for addressing a wide range of patient needs, whether that means creating a customized seat for a person with limited mobility or designing a prosthesis that fits the specific contours of an amputee’s limb. The software’s precision and adaptability make it a crucial tool for professionals in orthotics and prosthetics, as it allows them to move from scan to finished design with speed and confidence.

Cube’s uniqueness features

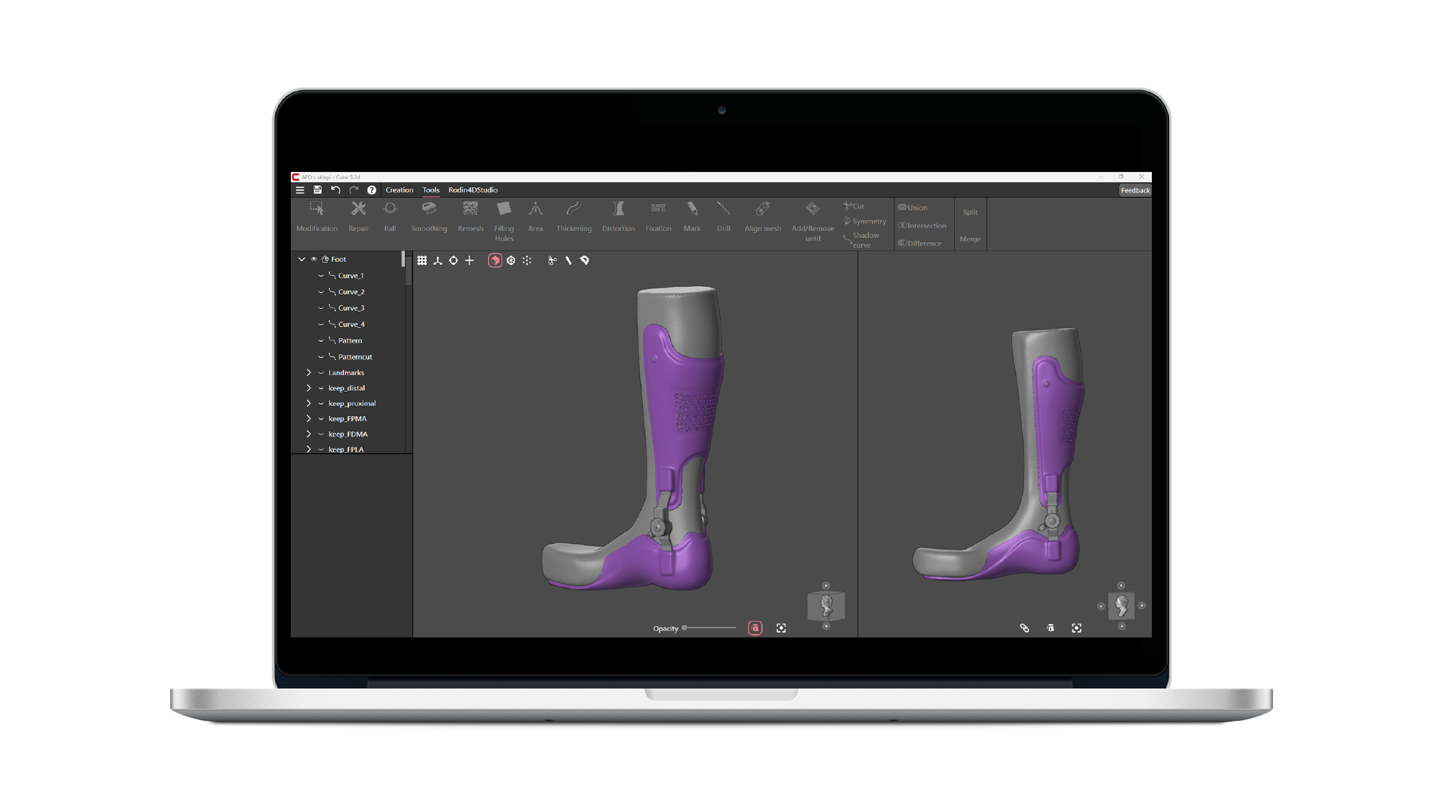

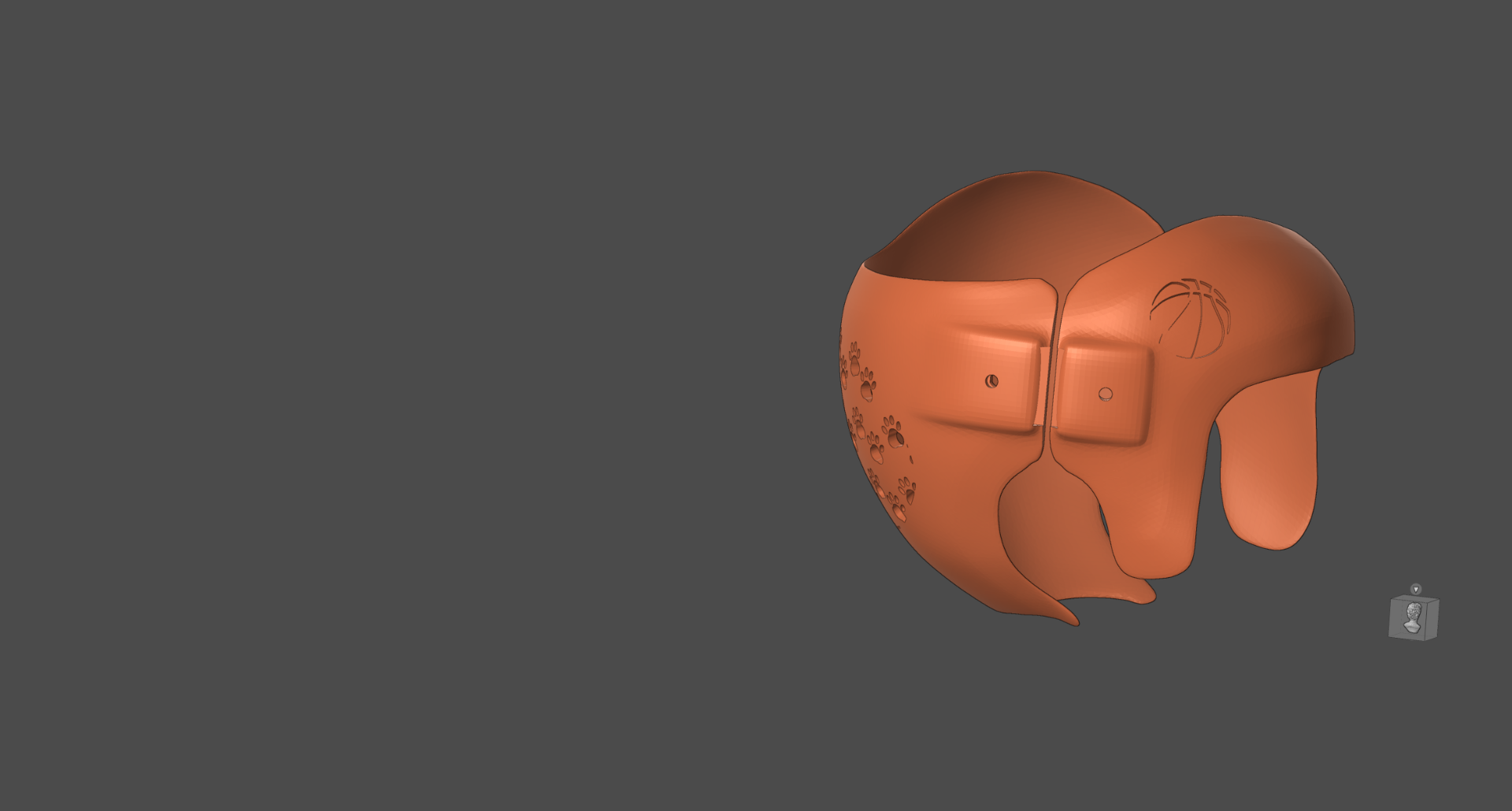

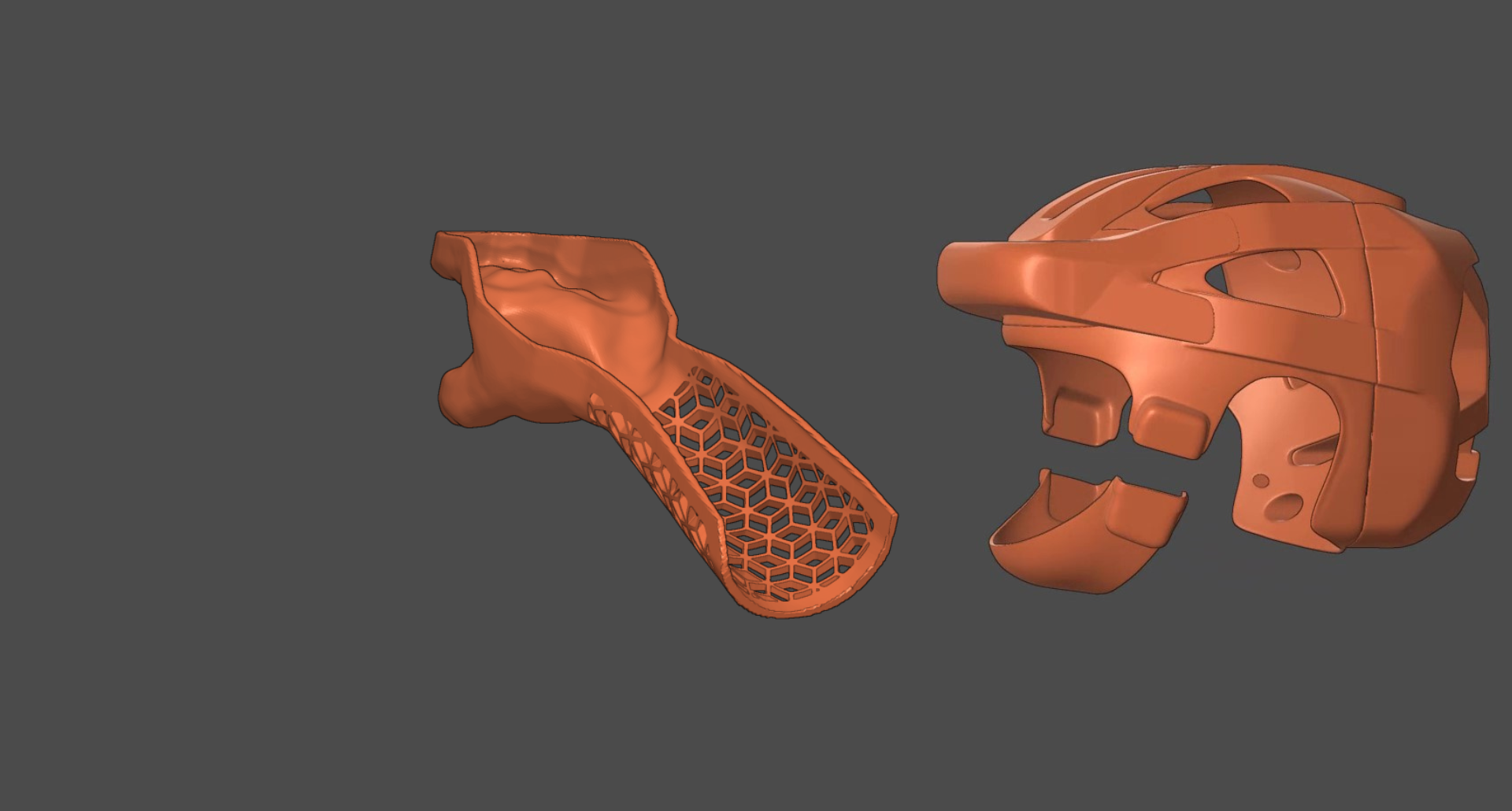

What truly sets Cube apart from other design software is its blend of versatility, ease of use, and specialized features tailored specifically for orthopedic professionals. It offers an expansive array of possibilities, making it ideal for crafting a variety of orthopedic devices. From seating and standing devices to specialized helmets and more, Cube supports the creation of all forms with precision and efficiency.

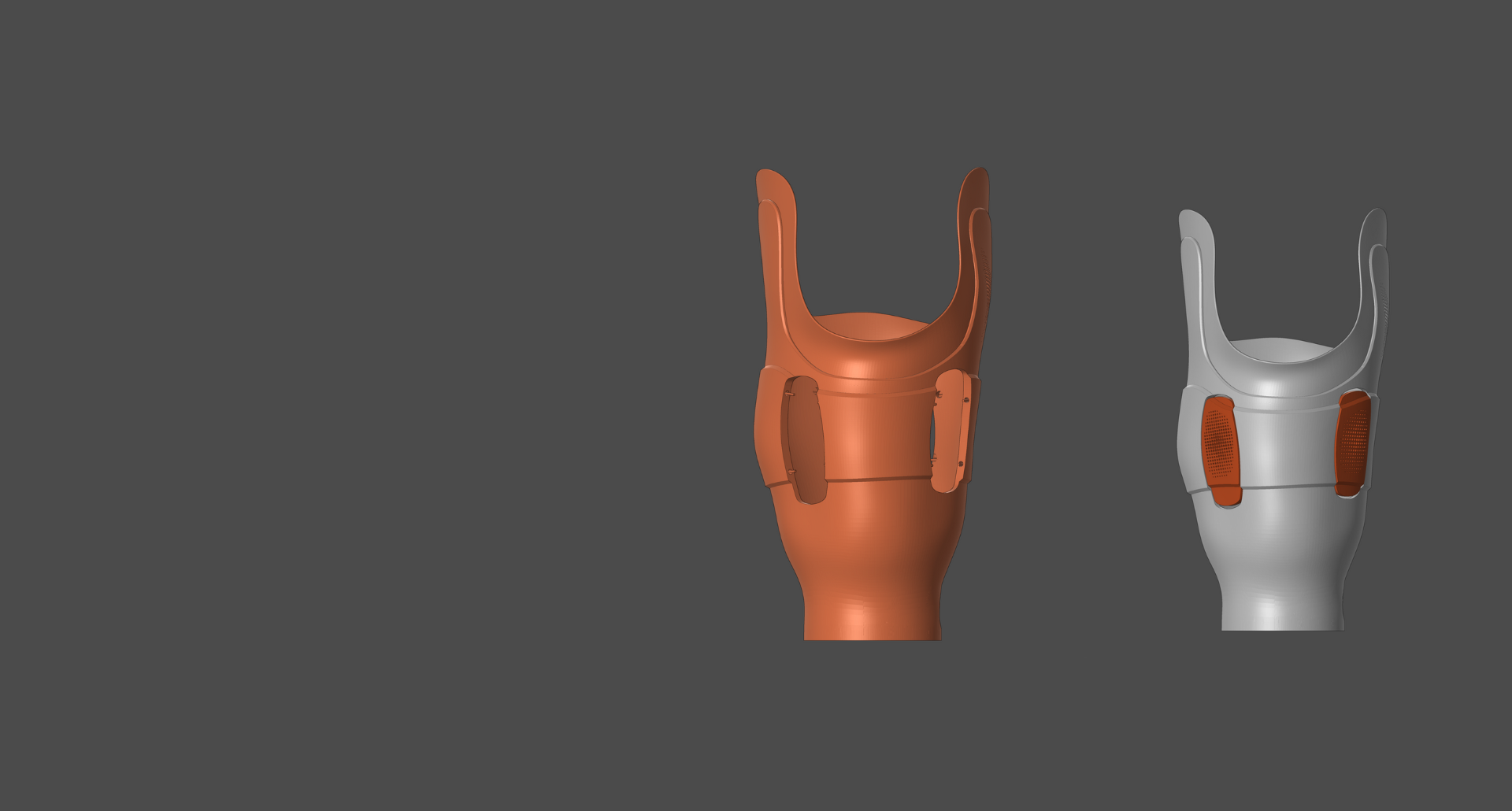

A key strength of Cube is its intuitive interface. Developed in collaboration with thousands of prosthetists and orthotists, Cube’s user interface was designed with professional feedback at its core. This ensures that users can access a range of specialized tools with minimal learning curve. Among its most notable features are the distortion tool, abduction angle adjustments, and customizable pad design options. These features allow professionals to easily modify and create complex orthopedic forms, ensuring that the end result is not only functional but comfortable and effective for the patient.

Moreover, Cube extends its capabilities to both 3D printing and milling, providing users with flexible options for manufacturing the designed devices. The integration with 3D printing allows professionals to rapidly prototype and create final, fully functional devices with unparalleled accuracy. Whether for rapid prototyping or final production, Cube ensures that professionals can achieve their goals without being restricted by manufacturing processes.

Limitless possibilities for orthopedic design

Cube’s unparalleled versatility opens up limitless possibilities for designing orthopedic devices, empowering professionals to create virtually any device needed in the field. The software’s range of specialized tools and customization options make it ideal for both simple and complex devices, ensuring a perfect fit for every patient.

Cube excels in designing positioning devices, helmets, prosthetics, AFOs and so on.

These capabilities ensure that Cube adapts to the diverse needs of the orthopedic field, providing solutions for both simple and highly complex projects.

Cube has become a true game-changer in the orthopedic field, an invaluable asset for professionals looking to push beyond the limitations of traditional software. With its advanced features, flexibility, and intuitive interface, Cube empowers users to design devices that perfectly cater to patient needs. The addition of 3D printing capabilities allows for seamless prototyping and production, further enhancing Cube’s impact on the orthopedic design process. In a sector where innovation and efficiency are paramount, Cube stands as the essential tool for orthopedic professionals, redefining the standards of orthopedic device design.

Read also :

3Dsizeme

Fitflow

Link

Canfit

MSoft

Liberty 2

My3Dsizeme

iMed file