In the field of orthopedics, precision and personalization are essential. Every patient has unique needs, making the design of custom devices both critical and challenging. However, traditional processes often involve significant time and effort. This is where Fitflow, an innovative orthopedic CAD/CAM software, steps in. By automating tasks and simplifying workflows, it enables practitioners to create high-quality, personalized orthopedic devices quickly and effectively.

Simplifying the design process from scan to 3D print

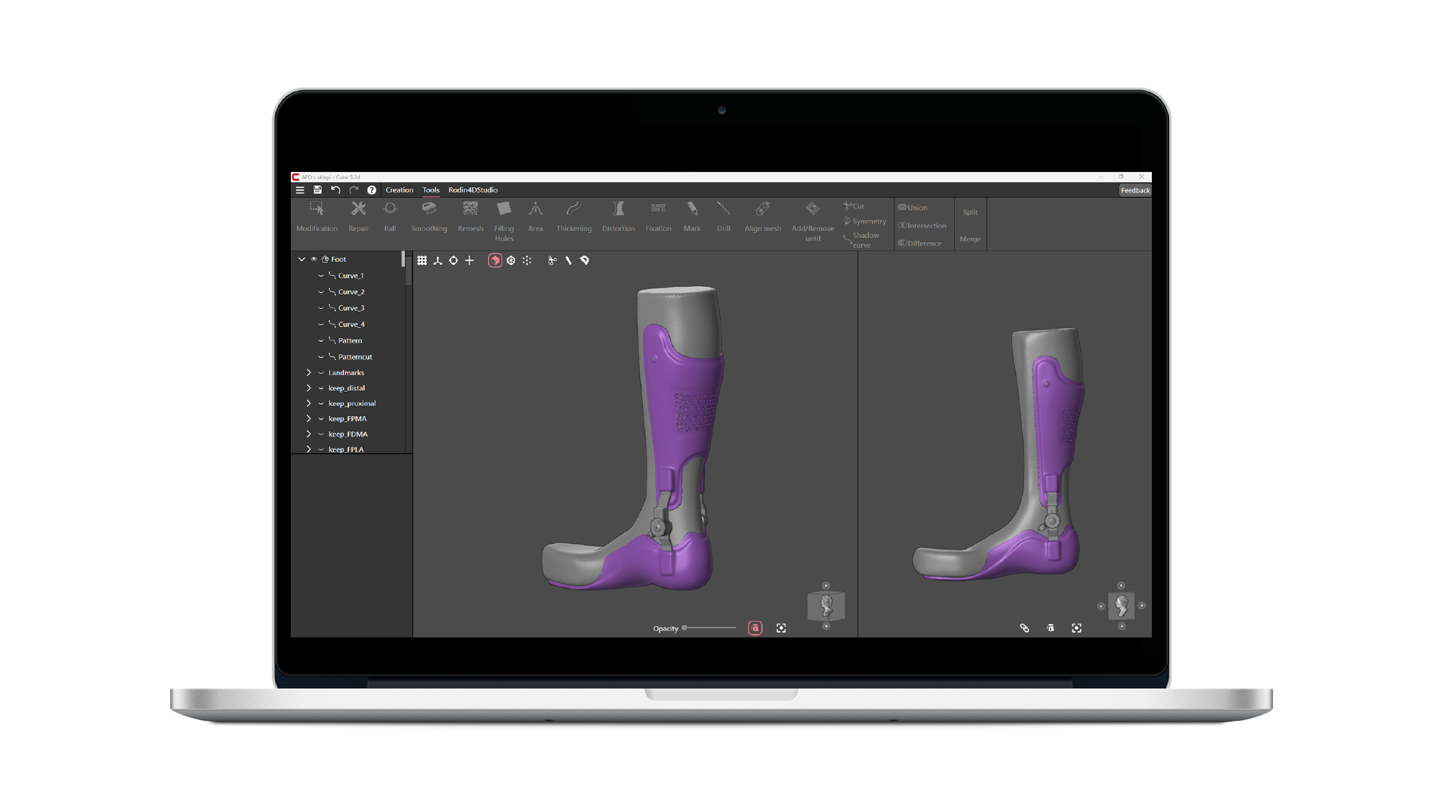

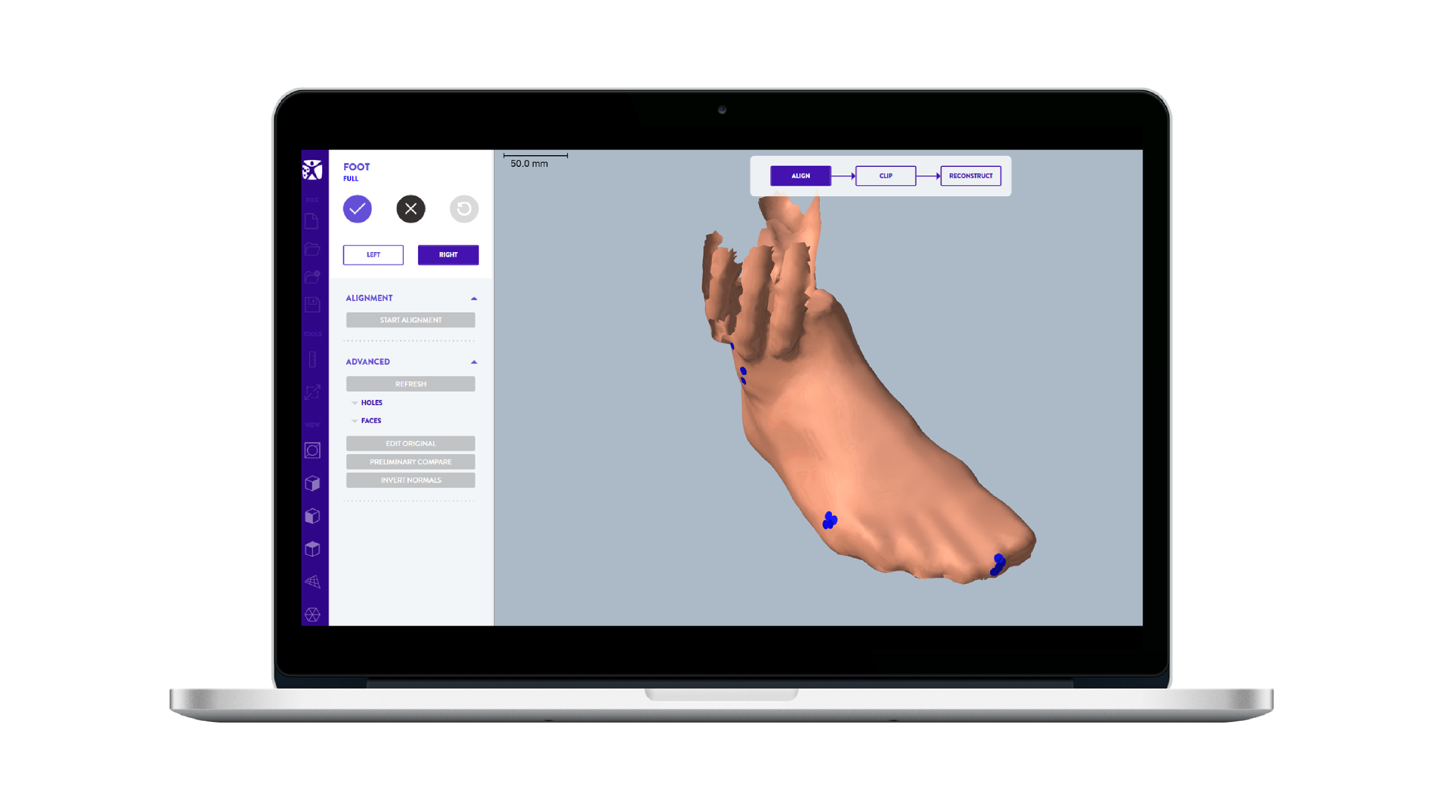

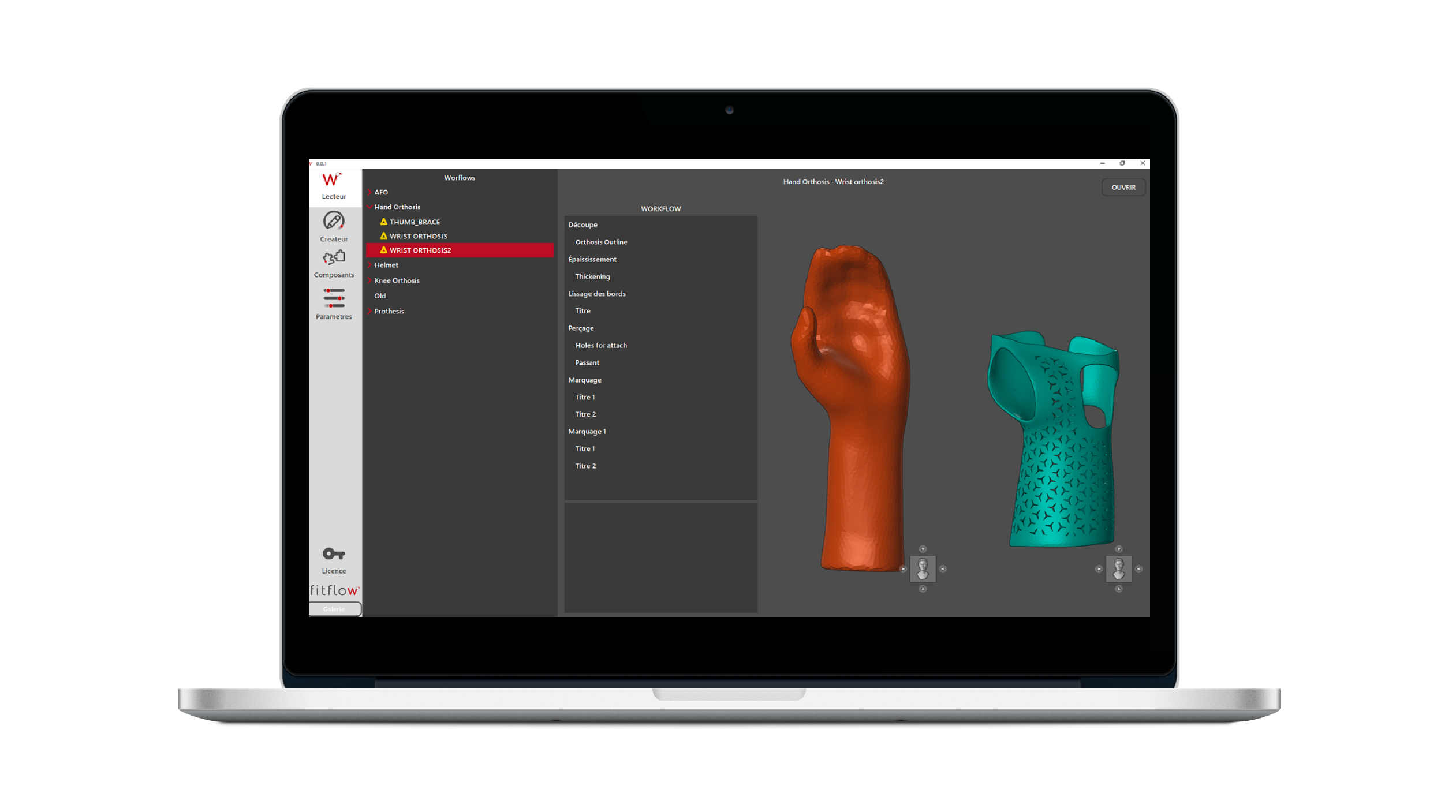

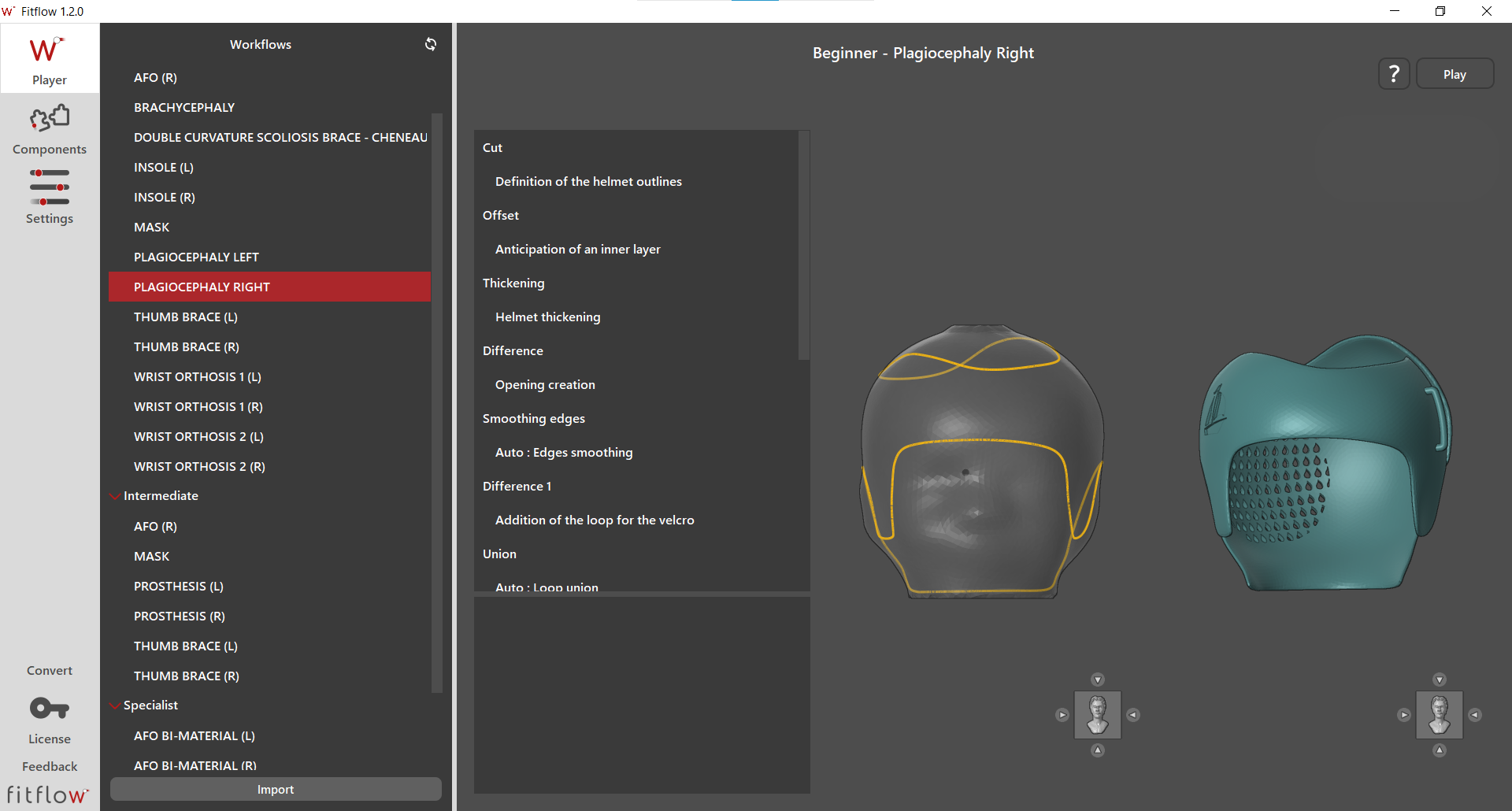

Fitflow makes creating orthopedic devices accessible for professionals, regardless of their technical background. The process begins by importing and cleaning patient scans, ensuring a precise foundation for design. From there, users can select predefined workflows among a library of more than 20 possibilities tailored for various devices such as hand orthosis, helmets, prosthesis, knee orthosis…

These guided workflows walk practitioners through each step, reducing design time to minutes. Once complete, the software generates an STL file, compatible with a wide range of 3D printers and materials. By automating repetitive tasks, Fitflow empowers users to focus on quality and innovation, rather than tedious manual adjustments.

Personalization meets automation: tailored workflows for unique designs

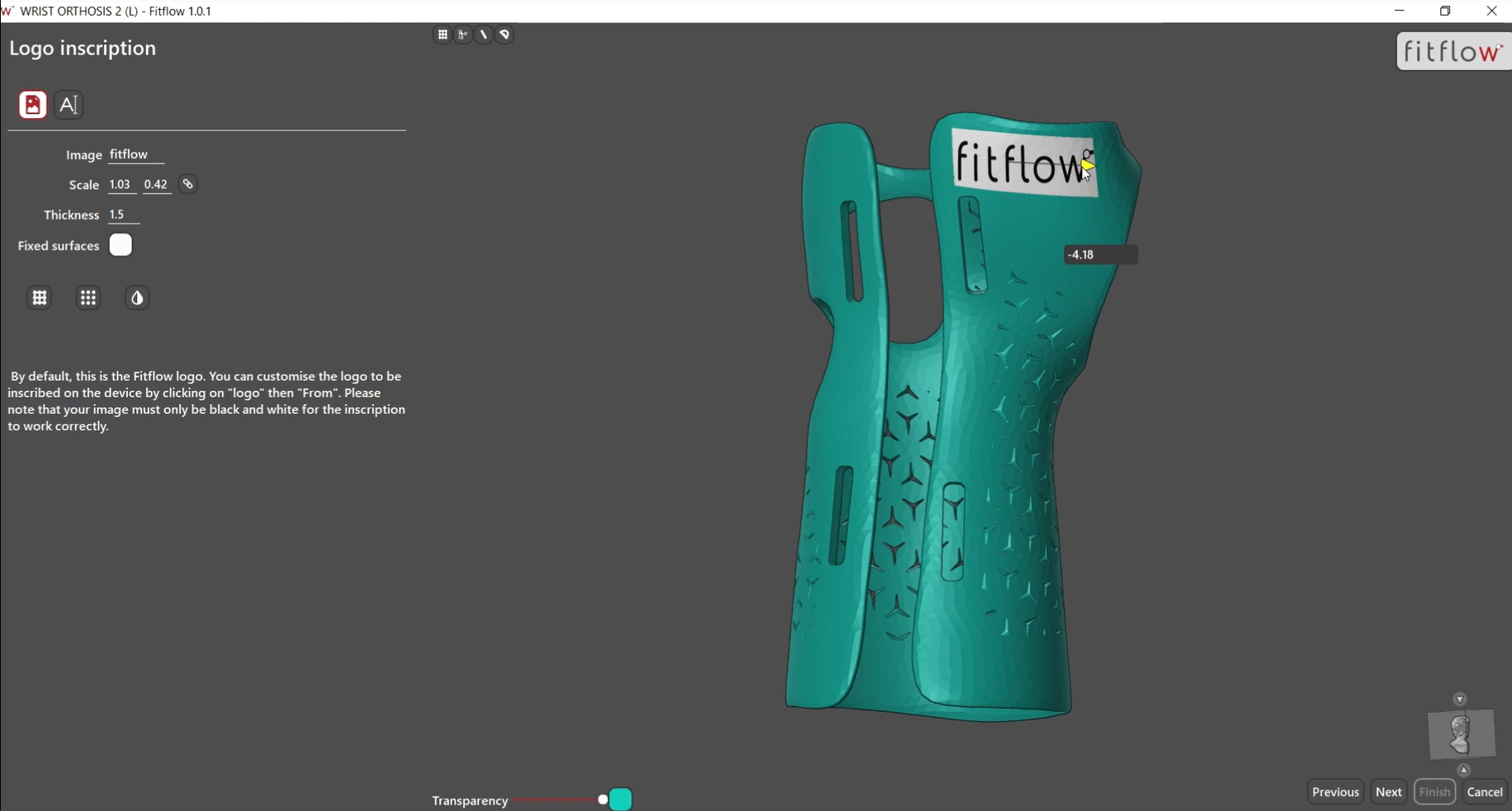

One of Fitflow’s key features is its ability to adapt to the specific needs of practitioners. The software allows users to customize workflows, creating a tailored design process that meets their exact requirements. Whether it’s adjusting for a specific patient’s anatomy or incorporating unique specifications, Fitflow ensures that every detail aligns with the practitioner’s vision.

The library of predefined workflows serves as templates that users can adapt and expand. This customization and automation not only increases efficiency, but also ensures consistently excellent results. In addition, real-time collaboration functions facilitate teamwork, enabling practitioners to share designs and optimize coordination within their teams.

Mastering mass customization in orthopedic design

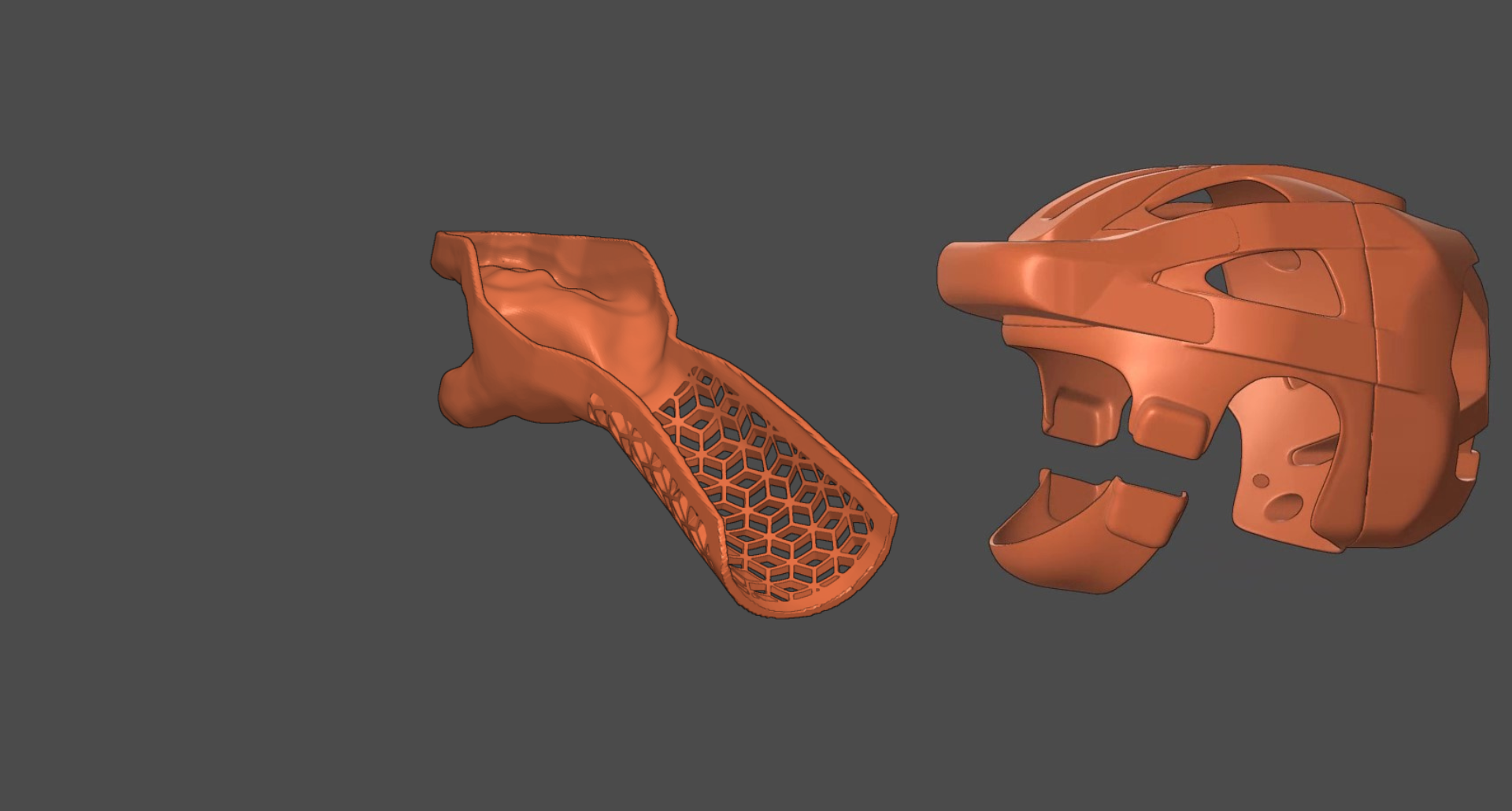

Mass customization is a growing trend in orthopedic appliance production, driven by the demand for large-scale, tailor-made solutions. Fitflow excels in this field, enabling practitioners to design customized appliances without sacrificing speed or efficiency. By automating key steps and providing intuitive tools for customization, Fitflow closes the gap between individuality and productivity.

For example, clinics and manufacturers can standardize certain aspects of their designs, while retaining the flexibility to adapt to individual cases. This approach not only reduces costs, but also improves the overall patient experience, by providing devices that fit perfectly and function optimally. Fitflow’s ability to streamline mass customization makes it an essential tool for modern orthopedic practices.

Fitflow represents a transformative step forward in orthopedic device manufacturing with the power of automation and mass customization while giving access to 3D printing to everyone. From simplifying design workflows to mastering mass customization, the software makes it easy for practitioners to achieve outstanding results and makes it possible to produce high-quality devices faster than ever before. With Fitflow, the future of orthopedic design is here – accessible, efficient and fully customizable.

Read also :

3Dsizeme

Cube

Link

Canfit

MSoft

Liberty 2

My3Dsizeme

iMed file