The field of orthotics and prosthetics (O&P) is continuously evolving, driven by technological advancements and innovative solutions. Keeping up with these emerging trends is crucial for practitioners to provide patients with the best possible care and outcomes. In this article, we will explore two significant trends shaping the landscape of orthotics and prosthetics: task automation with custom workflows and 3D printing technology

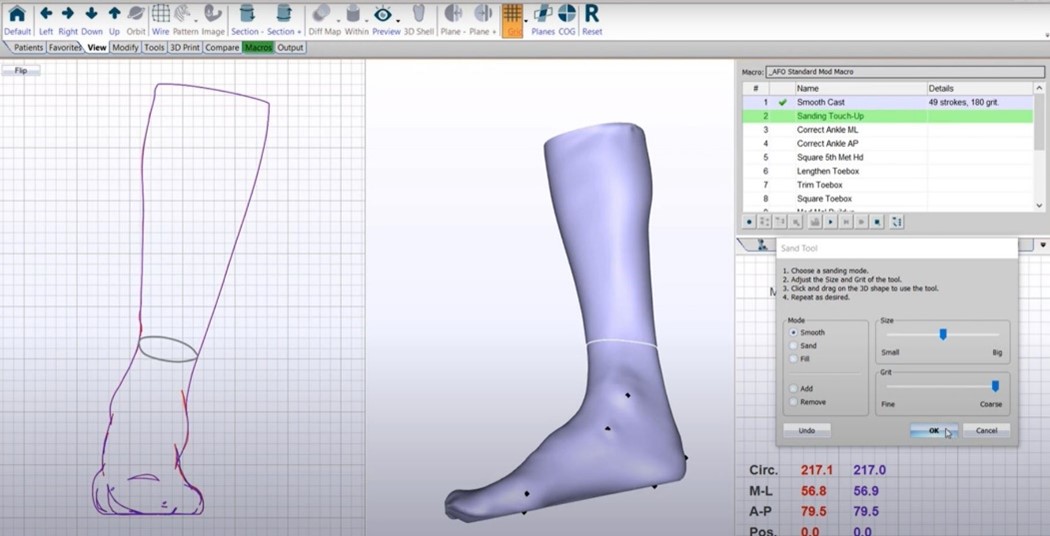

Task automation with custom workflows

Explanation :

Recently, the automation of tasks within the orthotics and prosthetics design process has revolutionized the way practitioners work. With the introduction of custom workflows, practitioners can streamline their processes, reducing technical constraints, and enhancing overall efficiency.

This process allows practitioners to create personalized workflows tailored to their specific needs and preferences. By automating repetitive tasks, such as the thickening stage, curve projection stage, and drilling stage, practitioners can save valuable time and focus more on delivering high-quality patient care.

Furthermore, custom workflows provided by Fitflow software, for instance, enable better collaboration among multidisciplinary teams, allowing seamless communication and integration of various stages of the design process. This improves workflow efficiency and ensures that each patient receives a customized orthotic or prosthetic device that meets their unique requirements.

3D Printing technology

Explanation :

Another significant trend transforming the orthotics and prosthetics industry is the widespread adoption of 3D printing technology. With advancements in materials and printing techniques, 3D printing has revolutionized the way orthotic and prosthetic devices are designed and manufactured.

The advantages of 3D printing are multiple. It enables practitioners to produce lightweight, durable, and highly customized devices that offer superior comfort and functionality to patients.

Qwadra’s Arkad Printer module exemplifies this innovation by offering practitioners a seamless integration of 3D printing into their workflow. This module provides advanced features specifically tailored for the podiatry field, allowing practitioners to create intricate insole designs with precision and accuracy. With 3D printing, your foot orthotics are ready for immediate use upon printing, eliminating any extra waste and noise in the process.

This flexibility empowers practitioners to explore creative solutions and push the boundaries of what is possible in orthotics and prosthetics.

Innovations such as task automation with custom workflows and 3D printing are reshaping the orthotics and prosthetics landscape. By embracing these trends, practitioners can streamline processes, enhance precision, and deliver personalized solutions to patients. Technologies like Qwadra’s FitFlow and Arkad Printer empower practitioners to focus more on patient care, while also fostering collaboration and creativity within the industry. As these advancements continue to evolve, practitioners will play a crucial role in driving improvements in patient outcomes and quality of life. The future of orthotics and prosthetics looks promising, with practitioners at the forefront of innovation, pushing boundaries, and shaping a more efficient and effective approach to care.