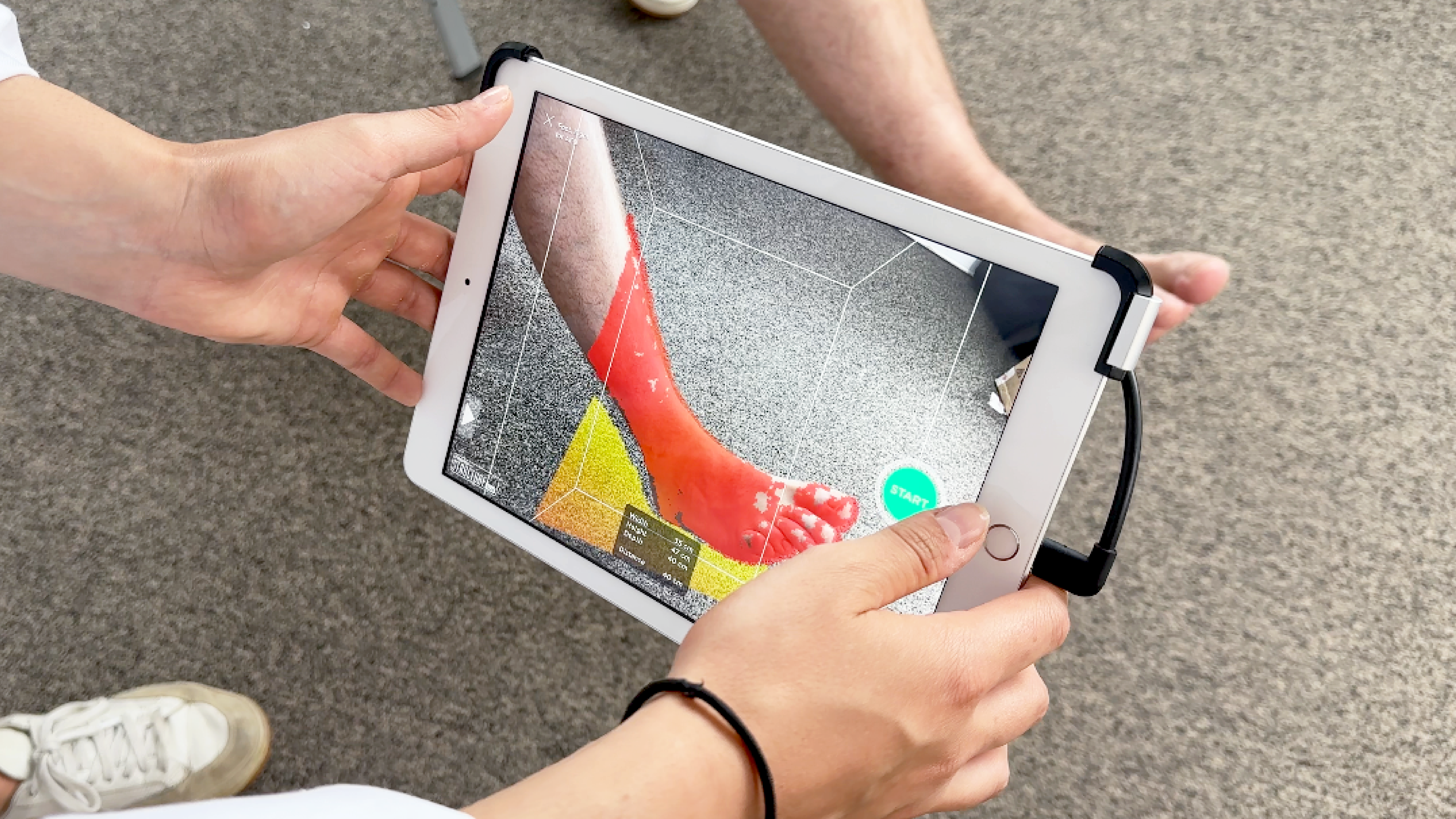

Scan your patient’s form

Non-contact 3D optical scanners capture your patient's shape much faster and with greater accuracy than plaster casts—without the mess or discomfort.

Modify the shape

Computer-based 3D design software tools allow for quick application of anatomical corrections to the scanned shape to create the desired form.

Create the mold or 3D print it

A high-speed carver automatically machines a precise, lightweight foam mold, or a 3D printer directly manufactures the device.

Milling machines are a cornerstone of the orthotics and prosthetics (O&P) industry, enabling the precise and efficient fabrication of custom devices tailored to individual patient needs. These machines provide a balance of automation and accuracy, streamlining production while ensuring a high level of customization. Additionally, when integrated with CAD/CAM solutions, milling machines allow for digital design and seamless workflow automation, further enhancing efficiency and precision in O&P manufacturing.

By leveraging advanced milling technology, O&P professionals can achieve improved consistency, reduce manual labor, and enhance overall patient outcomes. This article explores the different types of milling machines used in the industry, their respective advantages, and the impact they have on modern O&P manufacturing.

Types of Milling Machines

Qwadra 3 Axis Carver

The 3 Axis Carver is a fundamental milling solution, particularly well-suited for entry-level O&P applications. This machine is ideal for milling prosthetic and orthotic foam materials, providing precise and reliable carving capabilities. Known as our “Workhorse,” it is designed for durability and long-term use, offering a cost-effective solution for clinics looking to integrate milling technology. With its ability to deliver high accuracy while remaining user-friendly, the 3 Axis Carver is an excellent choice for facilities requiring consistent, repeatable results.

Axelle Carver (3 Axis)

The Axelle Carver takes 3-axis milling to the next level by offering rapid production times and superior finish quality. This machine is designed for high-speed manufacturing, capable of producing helmets in under two minutes, prostheses in under five minutes, and corsets within five to ten minutes.

With advanced acceleration control, vibration reduction, and seamless 7th-axis synchronization, the Axelle Carver minimizes machining increments, reducing cycle times and maximizing efficiency. Its ability to maintain precision at high speeds makes it an industry leader in automated O&P production.

Victor Compact (7 Axis) Carver

The Victor Compact is a powerful 7-axis milling machine, providing a higher degree of flexibility and complexity in shaping prosthetic and orthotic devices. Unlike 3-axis systems, which primarily operate in a linear motion, the Victor Compact’s additional axes allow for intricate, multi-directional carving.

This added flexibility enables the production of highly detailed and customized designs, making it an essential tool for professionals requiring advanced milling capabilities. The Victor Compact can also be upgraded to the Victor Compact +, which includes a second turntable for even greater production efficiency.

Victor Unlimited

As the most advanced milling machine in our lineup, the Victor Unlimited is designed for large-scale production. It offers enhanced automation and precision, making it ideal for high-output environments. This machine ensures consistency across multiple devices, reducing variability while maintaining accuracy. With its ability to handle diverse materials and complex designs, the Victor Unlimited is the go-to solution for facilities demanding the highest levels of productivity and precision.

1 Pair Insole Carver

Specializing in foot orthotic manufacturing, the 1 Pair Insole Carver is a dedicated milling solution for clinics focusing on podiatry and pedorthics. This machine is optimized for speed and precision, ensuring the efficient production of custom insoles tailored to individual foot anatomy. Its streamlined workflow enhances productivity, allowing clinics to produce high-quality foot orthotics in minimal time.

Vertical Milling Machines

Vertical milling machines are characterized by their upright spindle orientation, allowing for detailed cutting and shaping of materials. This configuration is particularly useful in O&P manufacturing, where precision and controlled cuts are crucial.

One of the main advantages of vertical milling machines is their precise control over cutting depth. This ensures that orthotic and prosthetic components meet exact specifications, resulting in better patient comfort and fit.

Advanced vertical milling machines are equipped with sophisticated tool control features, allowing for greater customization. Users can adjust speed, depth, and cutter type to optimize the milling process for different applications.

The flexibility of a milling machine is largely determined by its number of axes. A 3-axis machine is suitable for basic tasks, while a 7-axis system, such as the Victor Compact, enables complex, multi-directional shaping for advanced customization.

Various milling cutters are used in O&P applications, depending on the desired outcome:

Vertical machining centers (VMCs) are popular in the O&P industry due to their ease of use and precision. They provide a user-friendly interface and are highly effective for crafting complex prosthetic and orthotic designs.

The vertical spindle configuration allows for improved visibility and control during the milling process, making it especially beneficial for creating intricate orthotic designs that require fine detailing.

Horizontal Machining Centers

While less commonly used in the O&P industry, horizontal machining centers (HMCs) offer significant advantages for high-volume production. Their horizontal spindle orientation enables efficient multi-surface machining, making them suitable for large-scale manufacturing facilities.

Milling Machines in Product Manufacturing

The introduction of milling machines has revolutionized product manufacturing in the O&P industry. These machines provide:

By integrating advanced CNC technology, milling machines have enabled O&P professionals to deliver better patient outcomes while optimizing manufacturing workflows.

Conclusion

Milling machines have become an essential component of the O&P industry, offering precision, efficiency, and flexibility. Different types of milling machines cater to specific needs, from entry-level solutions like the 3 Axis Carver to high-end systems like the Victor Unlimited.

With continuous advancements in CNC technology, the capabilities of milling machines are expanding, further enhancing their role in custom orthotic and prosthetic fabrication. As the industry evolves, these machines will continue to play a crucial role in delivering high-quality, personalized patient care.

Read Also:

Don’t miss the latest updates and news for each of our solutions. You can unsubscribe at any time.

"*" indicates required fields