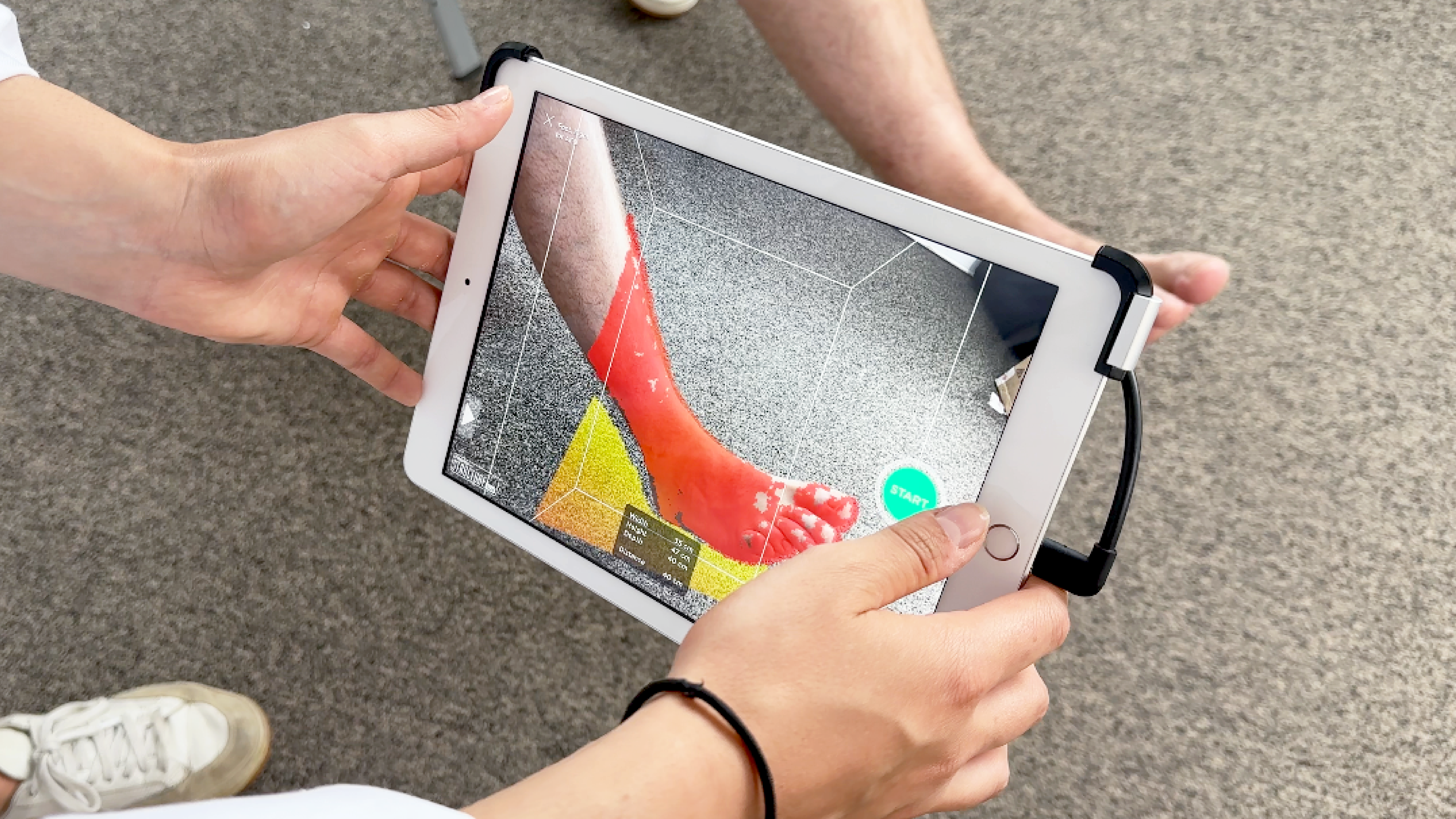

Scan your patient’s form

Non-contact 3D optical scanners capture your patient's shape much faster and with greater accuracy than plaster casts—without the mess or discomfort.

Modify the shape

Computer-based 3D design software tools allow for quick application of anatomical corrections to the scanned shape to create the desired form.

Create the mold or 3D print it

A high-speed carver automatically machines a precise, lightweight foam mold, or a 3D printer directly manufactures the device.

The Transformative Impact of 3D Printing Across Industries, with a Focus on Orthotics and Prosthetics

3D printing, also known as additive manufacturing, has revolutionized various industries by enabling the creation of complex structures with unprecedented precision and customization. Combined with advanced CAD/CAM solutions, this technology has significantly impacted sectors ranging from aerospace to healthcare, particularly in the field of orthotics and prosthetics (O&P). This article explores the evolution of 3D printing, its applications across different industries, and its profound influence on O&P.

Introduction to 3D Printing Technology

Three-Dimensional Printing

3D printing involves constructing a three-dimensional object from a digital model by adding material layer by layer. This process allows for the creation of intricate designs that are difficult or impossible to achieve with traditional manufacturing methods. The versatility of 3D printing has led to its adoption in various fields, including medicine, where it has been used to produce patient-specific implants and prosthetics.

Additive Manufacturing Techniques

Several additive manufacturing techniques have been developed to cater to different materials and applications:

Custom Printed Implants

The medical field has embraced 3D printing for the production of custom implants tailored to individual patient anatomies. By utilizing imaging data from CT or MRI scans, precise models of a patient’s anatomy can be created, allowing for the fabrication of implants that fit perfectly. This customization enhances the effectiveness of surgical interventions and reduces recovery times.

Patient-Specific Implants

Patient-specific implants are designed to match the unique anatomical features of an individual, offering numerous benefits:

Applications in Orthopedic Surgery

Surgical Planning

3D printing has become an invaluable tool in surgical planning by providing tangible models of patient anatomy. Surgeons can use these models to:

Three-Dimensional Bone Models

Creating 3D-printed bone models from patient imaging data has transformed orthopedic surgery. These models assist in:

Technology in Surgical Planning

The integration of 3D printing technology into surgical planning workflows has streamlined processes and improved outcomes. For instance:

Bioprinting in Orthopedics

Bioprinting, a subset of 3D printing, involves the layer-by-layer deposition of bioinks containing living cells to create tissue-like structures. In orthopedics, bioprinting holds promise for:

3D-Printed Insoles

Custom insoles address various foot-related issues by providing support tailored to an individual’s foot structure. 3D printing enhances this process by:

Orthotics and prosthetics have been particularly impacted by 3D printing. Custom 3D-printed insoles provide enhanced comfort, pressure relief, and biomechanical correction. Studies indicate that 3D-printed insoles can reduce plantar pressure by up to 30% compared to traditional options

Additionally, solutions like the Arkad end-to-end system for 3D printing insoles have made mass customization more efficient and accessible. Arkad integrates advanced scanning and design software with precision manufacturing to create highly personalized insoles tailored to individual biomechanical needs.

3D-Printed Wrist Braces

Traditional wrist braces often come in standard sizes, which may not fit all patients comfortably. 3D printing offers solutions by:

3D-Printed Prostheses

The advent of 3D printing has revolutionized prosthetic design and production:

3D-Printed Knee Braces

Knee braces support and stabilize the joint, particularly after injuries. 3D printing contributes to their development by:

3D Printed Spinal Braces

3D printing is also being used to fabricate custom spinal braces, improving patient comfort and treatment outcomes. Using our Cube software, along with the the Sona Edge printer, highly customized spinal braces are created with precision to support spinal alignment and alleviate conditions such as scoliosis. These braces provide a lightweight yet durable solution, ensuring better mobility and adherence to treatment.

3D Printed Seats

Custom seating solutions are another area where 3D printing is making a significant impact. With the Sona Flex printer, fully customized seats can be produced to match a patient’s unique anatomy. These seats provide enhanced pressure distribution and support, making them particularly beneficial for individuals with mobility impairments or complex seating needs.

Patient-Specific Applications

Patient-Specific Implants

The customization of implants to fit an individual’s anatomy has transformed patient care:

Custom Orthopedic Implants

3D printing enables the production of orthopedic implants that address specific patient needs:

Applications in Hip Arthroplasty and Foot Surgery

In hip arthroplasty, 3D printing has enabled the production of customized acetabular cups that improve the longevity and stability of hip implants. Similarly, 3D-printed foot surgery implants provide a better anatomical match, reducing recovery times and improving mobility.

Precision in Surgical Models

Surgical models printed in 3D offer unparalleled precision. By closely replicating a patient’s bone structure, these models allow surgeons to plan and execute procedures with greater accuracy, reducing surgical times and improving patient outcomes.

Utilization of 3D Technology in Surgery

Loss Prevention and Efficiency in Surgical Procedures

One of the biggest advantages of 3D printing in surgery is its ability to improve efficiency and minimize material waste. Traditional methods of manufacturing implants and surgical tools often involve excess material usage. Additive manufacturing, on the other hand, precisely deposits material only where needed, reducing waste and costs.

Hospitals that have integrated 3D printing into surgical workflows report shorter surgical times and improved patient satisfaction. For example, research from the American Journal of Surgery that 3D printing reduced operating room time by 20% in complex orthopedic surgeries.

Conclusion

The impact of 3D printing across multiple industries is undeniable, but its influence in orthotics and prosthetics is particularly transformative. From patient-specific implants to customized prosthetics and insoles, 3D printing has significantly improved the quality of care and accessibility of medical devices. As technology advances, we can expect even greater innovations in bioprinting, implant fabrication, and personalized medical solutions, shaping the future of healthcare for years to come.

Read also:

Don’t miss the latest updates and news for each of our solutions. You can unsubscribe at any time.

* Please fill out the required fields